We build rudders with passion and precision since 1963.

ships anywhere

cost effective

satisfaction guaranteed

about us.

In the early sixties, an innovative man named Chuck Foss developed several polyurethane foam systems useful for a variety of purposes, including the production of surfboards. His new firm, The Foss Company, soon became one of the top U.S. suppliers of foam surfboard blanks, which he sold under the name of “Foss Foam.”

Later in the sixties, one of his Foss Foam systems used to make surfboard skags was found to be an excellent material for making sailboat rudders. It was not long before The Foss Company supplied rudders to most of the boat builders in Southern California through the seventies and eighties.

The Foss Company’s former headquarters. During the eighties and nineties, the company specialized in fiberglass and foam composites. High performance sailboards and paddleboards were some of the products produced. With an extensive inventory of rudder molds, the company now specializes in supplying sailboat owners and boat repair yards with replacement rudders.

In recent years, The Foss Company has formed a strategic partnership with FinCo Fabrication, a major fiberglass manufacturing firm based in Santa Ana, California. This partnership will assure that The Foss Company’s long tradition of quality products and service will continue for years to come.

Our focus.

A custom design rudder can be made just for you and your boat.

CAL YACHTS

CAL 20

CAL 25

CAL 28

CAL 34

CAL 40

CATALINA YACHTS

CAPRI 18

CATALINA 22

CATALINA 25

CATALINA 250

CATALINA 30

CATALINA 45

ERICSON YACHTS

Ericson 35

Ericson 38

Ericson 41

Ericson 46

BENETEAU

Oceanis 37

Oceanis 46.1

Beneteau 56

Manufatures A-C

Balboa Yachts

B-Boats

Beneteau

Catalina Yachts

Cal Boats

Coronado Yachts

Columbia Yachts

Coastal Recreation

Chrysler Yachts

Corsair Marine

C & C Yachts

Manufatures D-L

Down East Yachts

Ericson Yachts

Hunter

Hobie Cat

Irwin Yachts

Islander Yachts

J Boats J24

Kirby Boats

Kettenburg Marine

Lancer Yachts

Laguna Yachts

Manufatures M-R

Merit Marine

Morgan Marine

MacGregor Yachts

Newport Boats

Olsen Boats

O’Day Boats

Pearson Yachts

Pacific Sea Craft

Ranger Yacht

Reynolds Sailing

Manufatures S-Z

Sam Morse Boat Company

San Juan Boats

Sidelmann

Tarten Marine

W. D. Schock Boats

Westsail Marine

Westerly Marine

Willard Boats

Start your rudder with us now (714) 973-2878 or (949)646-0244

Our manufacturing process.

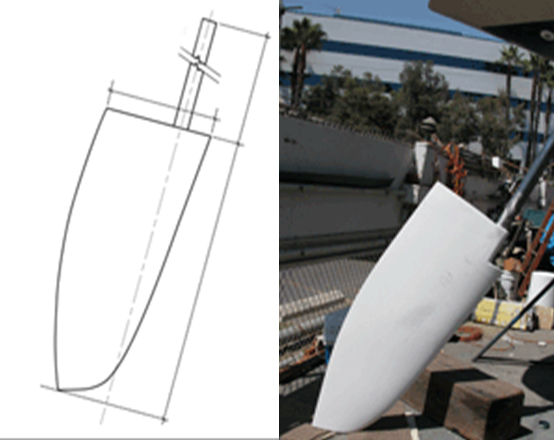

Design

Working together with you the owner we select an exciting mold or sketch out a new design for a custom rudder. All based off years of experience and time tested best practices.

Prepping mold

Experienced Finco craftsmen begin the manufacturing process by sanding, polishing and waxing the rudder mold.

Gelcoat & first layer

After applying Gelcoat to the mold, they apply a layer of unidirectional fiberglass saturated with Vinylester™ resin.

Rudder Shaft Turned

A new rudder shaft is turned from the same material as the original (or stronger.) After it is cut to length and tapered, the tangs are welded into place.

Shaft set & foam+

Once the fiberglass has cured, the tapered stainless steel shaft is set into the mold. After the shaft is aligned, the halves are mated, clamped and sealed, and liquid foam is poured into the mold.

Sand to Smooth

When the foam has cured, the rudder is removed and the seams sanded smooth. Most OEM rudder fabrication stops here; we go farther.

Taped and cured

Fiberglass tape is laminated to the seams. After the tape has cured and has been sanded smooth, the rudder gets a final coat of gelcoat.

Faired & prepped

In the last step, the entire rudder is faired and sanded in preparation for you to apply a coat of bottom paint.

Packed in custom box

The finished rudder is packed in a purpose-built crate suitable for shipping to you anywhere in the world.

Start your rudder with us now (714) 973-2878 or (949)646-0244

Why Select Us?

OEM Tooling

We have many of the original molds and tooling for production boats made over the mast 60+ years in our inventory and can replace damaged rudders with the exact factory replacement. If you would like a custom rudder, we can modify or design from scratch a rudder that meets your exact needs.

Smart Advancements

The original rudders originally were manufactured by “clam-shell” method and our exact replacements use the same tooling. Plus over the years there have been advances in glass cloth and in laminating resins making them stronger and more reliable. The closed cell foam core of the rudder remains the same, but the selective addition of unidirectional fibers has increased the strength of our rudders, and the use of Vinylester™ resins has eliminated blisters and the need for expensive barrier coats.

Performance Upgrades

Newer designs to improve handling and directional control. This is most important when sailing very fast and can help prevent broaching and spin-outs. Most boats can use upgraded rudders without incurring a rating penalty. Some local PHRF boards will hit some designs with a 3 seconds-per-mile penalty so you should check with your local board before making your change.

Start your rudder with us now (714) 973-2878 or (949)646-0244

Get in Touch

Here for you

Phone: (714) 973-2878

(949) 646-0244

Email: finco@sbcglobal.net

About us

Foss Rudders fondued in 1963 has partnered with FinCo Fabrication, a major fiberglass manufacturing firm in Santa Ana, California. We make precision rudders for you.

Where to find us

2520 South Broadway, Santa Ana CA 92707